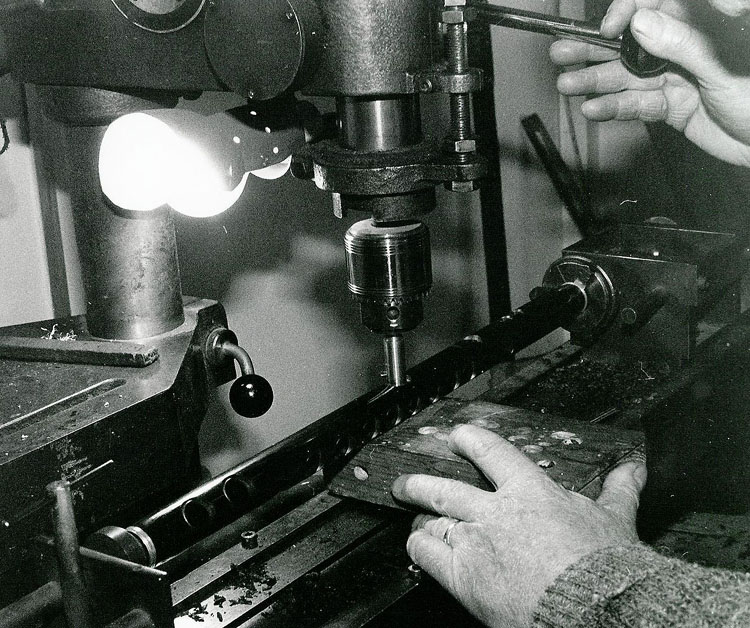

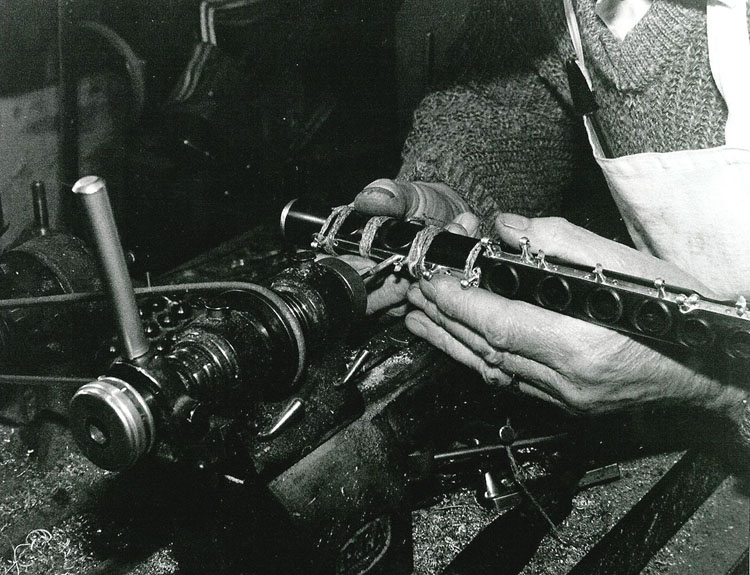

A Rudall Carte TransplantInterim IntroductionSensing my interest in historically significant flutes, professional flute player Nigel Street contacted me from his home in Cypress to talk about a project carried out some years back. The project involved taking the keys from a high-pitch Rudall Carte & Co flute and transplanting them onto a new modern-pitch body, giving the grand old flute a whole new lease of life. Nigel was able to supply me with photos taken by the craftsman Harry Seeley that illustrate how the project was carried out. I was able to track down Harry and get his permission to use the photos. Important NoteI have left the images below large to preserve the detail - I apologise that it will take a long time to download. I suggest the first time you download it, you save it to your own system, so you don't have to download it again. Wait until the whole page has loaded, then select Save or Save As in your File menu. Accept or modify the details and press OK. Background to the projectI asked Harry to tell us about himself, Rudall Carte and the Flutemaker's Guild ... |

|

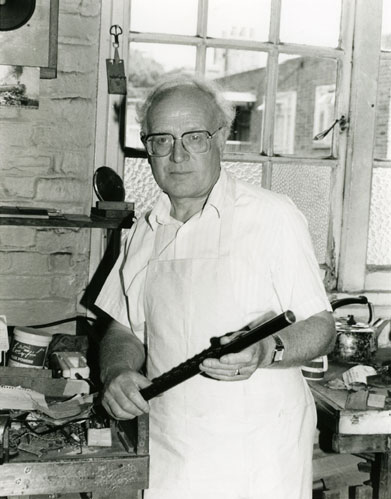

| My name is Harry Seeley and I started work in 1948 making

six key band flutes with a firm called Henry Starck, who also made

Bagpipes. After doing my National Service I went to work for

Rudall Carte in 1956, staying till 1961 when the Flutemakers Guild was

formed. I stayed there till ill health forced me to retire in

1998.

At the time that I went to Rudall, Carte in Berners Street the business was already owned by Boosey & Hawkes; in 1958 it was moved to premises in Islington, London, N1. After B & H had a bad financial year in 1960 all outside small businesses owned by B & H were moved to the B & H factory in Edgware, Middlesex. Some of the R C staff did not want to make this transition as the journey was too great and thus the Flutemakers Guild was formed. Those who stayed with RC carried on for some years but eventually it ceased to exist, my knowledge of these years are heresay as I wasn't involved. The Flutemakers Guild was formed by a small group of RC workers in 1961, myself included, as I have stated, first at 48 Broadwick Street, London, W1 and then at 10, Shacklewell Road, London, N16. |

|