Introduction

OK, OK, this isn't really

much of an innovation,. The combination of a flute making workshop

and rooftop solar power. But I had to find somewhere to put

it.

And maybe it isn't an innovation at all -

maybe the world is buzzing with flute makers already using solar power

to drive their workshops. But maybe that's not the point.

Maybe the point is that now we can! And, if we can, then perhaps

we should. So, humour me!

And the time is right to look

at this. The COP21 talks in Paris on saving the world from

calamitous climate change are just wrapping up as I type.

Hopefully they will end well and we can start turning our big ship

around, sailing for better weather.

(Update. The COP21

talks in Paris did go well, with universal agreement we will act on

reducing emissions. Now we wait to see how the world matches words

with action. I'm pretty confident. Anyway, back to our

story...)

Solar power in Australia

Solar power is increasingly

popular in Australia. We have about 9 million households, of which

1.4 million have rooftop solar (as of late 2015). That's nearly

16% of households. And for good reason -

we have sun, lots of sun. And mostly clear skies. And our

electricity prices are high, but the cost of photovoltaic systems is

dropping fast. Which is good, as we have the highest per-capita

output of CO2

emissions in the world! Abundant supplies of coal have left us

lazy.

Making solar power work

Now if you've ever looked

into the viability of rooftop solar, you'll have spotted the catch.

The electricity companies are happy to accept your energy contribution

to the grid, but less happy to pay for it. In our area it works

out like this. 1KWHr of energy from the grid costs about 22cents.

The same amount of power fed into the grid earns just 6 cents. The

companies can mount any number of arguments in support of that 360%

imbalance. We can mount a similar number in opposition. But

unfortunately, they win. For the moment....

So the take-home message from

all that is that it's much better if you can use the energy you

generate, rather than let it go into the grid. And that's often a

problem for most workers. While the sun is shining, they are away

at work. You might be able to program the dishwasher to kick in at

10:00, and the washing machine to kick in at 11:00, but how to use the

rest of the day's incoming energy productively?

But the flutemaker is in a

different position. You're at home during the day, cranking out

flutes. Hey, this has possibilities....

How much energy?

So how big a system would we need? Let's look at

the big machines. The circular saw, used to cut up blanks, 2HP.

The big metal lathe, used for reaming and other heavy tasks, also 2HP.

Woodlathe, used for faster work, 1.5HP. Big bandsaw, ditto.

Mill, used for drilling and slotting, 2HP. Compressor, 2HP. Drill press, 1.5HP.

Because I mostly work alone, only one gets used at a time. We pick the

larger, 2HP, or in modern language, 1.5KW. But wait!

While the big machine is running, so is the dust extractor, also 2HP, or

1.5KW. And maybe 1KW of lighting. So that's adding up to 4KW

power demand. Ah, but wait again. While all that's

happening, I might be running the CNC lathe and its computer, controller

and dust extractor, which would take us over 6KW if all fully loaded at

the same time. OK, short

answer, as much power as we can get!

Will that fit?

So that brings us to what's feasible, both physically

and financially. And that brings us to examine the physical

constraints. The back of our house faces almost exactly north,

within half a degree. And in the southern hemisphere it's the

northern roof we want. But we also have forest on that side, and our

eucalypt forests are something to behold. The trees rise 40 metres

(131 ft) from the forest floor. Fortunately, the nearest are far

enough away that we have no shading problem for most of the year.

But for the month or so each side of the winter solstice, the lower part

of the northern roof does suffer some shading. And that made us

reach for a special solution. A problem with a single

string of solar panels is that if any of them are shaded, it reduces the

efficiency of the entire string. So we went with a two-sting

inverter. The panels at the top of the roof form one string, those

at the bottom the second. If the forest shades the lower panels,

the upper panels will keep cranking out power. That's a

slightly unusual application of a two-string inverter. They are

mostly used when panels have to be split over two sides of a roof, eg

half to the north east, half to the north west. But it works to

our advantage here. So, what we could use and what would

fit led us to a specification. We should be able to fit a total of

twenty 250W panels, which neatly breaks into two strings of total 5KW.

Installation day

Installation day arrived, and we faced it confidently.

We'd come up with the plan to use the two-string inverter for the upper

and lower set of panels on the roof, and the installation company had

agreed to that. But, when boots hit roof, a complication

arose. Although there was room for the lower string to go along

the bottom edge of the roof, there was only one accessible row of

roofing screws. The installers make use of the existing roofing

screws on corrugated iron roofs, and they need access to two rows.

The installers said, don't worry, we'll put the second string on the

western roof - you only lose about 10% of energy. That might be

all very fine on open flat land, but we have a massive forested hill to our

west, and that would knock out a few hours of sunlight. So no go!

Everybody put their thinking caps on, and we struggled to come up with a

viable solution. Finally it was the installers who hit jackpot.

Split the intended bottom row of 10 panels in portrait mode into two

banks of 6 and 4 panels in landscape mode and they could find enough

screws to secure it all. The upper string had to be split

too, but into one row of 5 panels, and a second row of 3 and 2 panels,

all in portrait mode, in order to get around our solar hot water

service. Looks a bit messy, but the only people who can see it are

the wallabies who live in our forest.

Now it's not easy to get an image of your roof, so please excuse the

rather cluttered image above. The odd hexagonal frame at left is

not an antenna for communicating with extraterrestrials (that's around

the other side of the house), just the frame of a gazebo we put up in

summer to shade our outdoor eating area. The two grey panels in

the centre of the roof are solar hot water panels which also work

fabulously to keep our hot water costs to a minimum. The other

(blue) panels are the new solar array. You can also see a

small extract of the wide blue skies we have down here. What the

residents of Beijing would pay for a chunk of that over their house!

Ignition

The day before the panels were installed, a registered

electrician had come to install the new bi-directional power meter, so

once the solar panels and the inverter had been installed and wired, we

were ready to go. And go it did, generating over 4KW at midday

even though it was early spring and the sun was still relatively low on

the horizon. At the time of writing (late spring - December),

we often see it top the theoretical 5KW maximum.

Monitoring

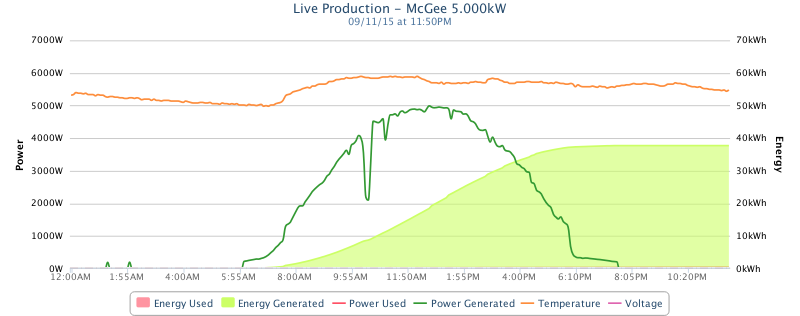

As a fully-diagnosed and registered data freak, I need

to know what amount of energy we are generating and what we are using,

so I've installed a Current Cost metering system to keep track of that.

Data is captured every 5 minutes or so, and automatically sent to a pair

of monitoring sites on the web, which return it nicely graphed for your

edification. It confirms that on a good day we can expect to

generate more than 35KWHrs of energy (light green shaded section of

graph). The thin green line shows the actual power generated at

any time throughout the day. You can see how that fits in nicely

with the working day.

I believe you can monitor the output of our system from the

convenience of your own device (how weird is that!).

Try it:

McGee

5000W

At the time of writing, I can't take full advantage of all the system

can show, as I'm waiting on delivery of the Gateway needed to send

multiple channels of data. I'll update the graph when that

happens.

Update!

And it has happened. My new Gateway arrives, and after a few

hassles, we get the data collection going. As you can see, the

image below is similar to the image above, except we now have two

power-related traces:

-

The thin green trace is power generated. It

follows the usual pattern of rising in the morning, peaking around

noon and fading in the afternoon that we saw above, except on the

day there were some periods of heavy cloud.

-

The thin red trace is monitoring the energy consumed

in the house and workshop.

The burst of consumption starting around 6:30am was the breakfast rush,

unfortunately outside of generation time, but we're not going to be

ruled by this monster! Jesse also absentmindedly ran the washing

machine, rather than waiting for more sunlight. We're still

getting used to this!

But the five big spikes later in the day were me in the workshop, boring

flute blanks. And that was the perfect job to test the system.

To bore flutes, I use a gun-drill mounted on the metal lathe carriage.

This means that the 2HP lathe motor is not only rotating the blank, but

also power-driving the carriage towards the chuck, advancing the

gun-drill through the work. It's all done at the highest speed

available, and at a fast feed. That's pretty demanding, and you

can hear the motor slow a semitone as the drill engages the hard

end-grain of the very hard wood.

But as well as that, the 2HP compressor is in use, pumping compressed

air through the gun drill to clear cuttings out, to prevent the drill

from binding. And of course that means we would be spraying dust

and granules everywhere, if it were not for the 2HP dust extractor

sucking it all up.

So that's a total of 6HP, or 4.5KW of potential demand. Perhaps

5KW with lighting. And we can see on the red trace that I did 5

bursts of gun-drilling spread throughout the day to give man and

machines a rest. Plus a few other jobs around the workshop, but as

you can see, they didn't use that much power. The small peak just

before 4:00pm also involved the metal lathe, but not the other two

machines. And the job was undemanding - just turning a small piece

of Delrin for a thumb-rest.

We can see that even this highest level of power demand generally came

within the generation envelope (the green trace). But clearly, one

should only gun-drill when the sun shines best.

We can also learn something from the pink and green shaded areas of the

chart. They show the total energy (in KW-Hours) that we consumed

(pink) and generated (light green) integrated over the day. You

can see we generated 32KWH, used 18, and thus contributed 14KWH to the

grid, a net boon to humankind. We can have our cake and eat it

too!

Cost and returns

So, what did it end up costing? About $7500AUD, or

USD $5300. Or in "Irish music international exchange units", about

1.6 six-keyed flutes. That's not really a lot, is it.

It's obviously going to take about a year to know what impact it's had

on our electricity costs. One reason for that is that we need to

see the full set of seasons, but I've done some modelling on results so

far, and it's looking promising. It looks like it should halve our

domestic electricity bill and that represents a return on investment of

about 12%. That means it should pay itself off in about 8.4 years.

Since the system should operate for 25 years or so, that should keep us

in low-price electricity till some new technology replaces it.

But, whatever the financial impact, it's nice to know we are generating

more energy than we are using. And perfectly clean energy at that.

In these climatically-challenged times, that's priceless.

Ah, now the sun has come out, so it's time for me to get down there and

make some solar powered flutes! |