A.D. 1785 - No. 1499Potter’s German fluteIntroductionIn 1785, Richard Potter patented his remake of the English "German flute". His Patent Flute sold very well, and influenced the direction English flutes were taking. Here we look at his patent document. I'll add some notes along the way to draw your attention to interesting detail, or to clarify obscure terms or passages. I'll also add paragraph headings, and alter and repunctuate it for easier readability - whether it was the style of the time or a legal construction required by the Patent Office, the sentences in the original can run to half a page! Note also that I've dictated the contents of the Patent via voice recognition software to save typing (my copy wasn't up to scanning). There may be some minor errors I have not corrected so don't rely on the document for critical purposes. I'll also leave out the rather tedious formalities. As usual, copies of the full document can be obtained for a very reasonable price at the Patent Office in London. What had preceded Potter's Patent German flute?Before we see the details of the new instrument, we should familiarise ourselves with what one of his flutes looked like a few years before the Patent came out. This one is in the Bate Collection in Oxford; the images kindly supplied by London flute maker and researcher Robert Bigio.

Of particular relevance, we can see the single piece head (tuneable over a short range only by pulling the head out on the tenon like a recorder); the simple flat plate leather-backed keys that had been used since the invention of the 1-key flute, and the three LH sections, corps de rechange, that extended the tuning range to cover the range needed at the time. Potter’s German flute[I must admit total defeat in editing Potter's first sentence, the preamble that sets out the scope of the invention claimed. It's hard to see how to make it better sense without complete revision! My version appears below Potter's.] Scope of the invention, Potter's versionMy said invention is an improvement upon the musical instrument commonly called the German flute, and which invention is also, as to part thereof, applicable to and an improvement upon most of such other musical wind instruments as are played upon with keys, consists of and in the use and adaption of the metal pipes or tubes hereinafter mentioned and described to the said instrument called the German flute, and also consists of and in the construction, manner of making, and adaption to the said musical instrument called the German flute, of the keys with valves, as hereinafter mentioned and described, and the metal pipes countersunk to receive them as hereinafter also mentioned and described, and which keys with valves, and which last mentioned metal pipes so countersunk to receive them as aforesaid, are applicable and capable of adaption to most of such other musical wind instruments as are played upon with keys, and will, if applied and adapted to them, be an improvement thereon; and my said invention is to be performed, and the said metal pipes, tubes, keys with valves, and countersunk metal pipes, are to be used, constructed, put together, fixed, and applied in the manner particularly mentioned and described in the drawing or playing sub joined, and the explanation following, by which I refer to the said drawing or plan (that is to say): -- Scope of the invention, McGee version:Potter's patent application is for a flute incorporating the following features:

(Note that Potter doesn't claim to have invented all these features - the application is for a flute with these features, not the features themselves.) Now, back to Mr. Potter... The headThe German flute is made to draw out to time to other instruments. [Potter's use of the expression "to time to other instruments" is a bit odd. Conceivably, he's talking about matching wavelengths, in which case the verb "to time" has some applicability, but that seems unlikely. Remembering that the patent documents were all typed up some years later for publication in 1856, it's probably a mistype for "to tune to other instruments".] The head and bottom joints are made in two pieces; the longest piece of the head A is 6 inches and a half [165mm] long ; the shorter one B is 3 inches and a half [90mm, including protrusion] long. The longest piece A has a groove [socket] turned in at the lower end to receive the shorter one B, which is turned smaller 1 inch and a quarter [32mm] long to fit and slide into the groove [socket] turned in the longest piece A to receive it. The longest piece A is lined with a metal pipe C three quarters of an inch [19.05mm] diameter and 7 inches three quarters [197mm] long, which comes through the lower end 1 inch and a quarter [i.e. protrudes ~32mm]. The shorter piece B is likewise lined with a metal pipe D, 2 inches and a half [63.5mm] long, and made to fit and slide on the longer pipe C, and into the groove [socket] of the longest piece A, and forms a double sliding joint air-tight.

Left hand sectionThe second joint (A, A), commonly called the middle joint, is about 6 inches and a quarter [159mm] long, exclusive of the pins [tenons] at each end, which are turned down to fit to the other joints. The joint has two keys, one for the note G#, that is to say G Sharp; the other for the note Bb, that is to say B-flat, which are placed as on the draft [below].

Right Hand SectionThe third joint (B, B,) is about 5 inches [127mm], exclusive of the pin [tenon] at the lower end, which is turned down to fit the bottom joint, having the key for the note F natural, which is placed on the draft; these joints are often made without keys. [I.E., these joints on a one-keyed flute are devoid of keys.]

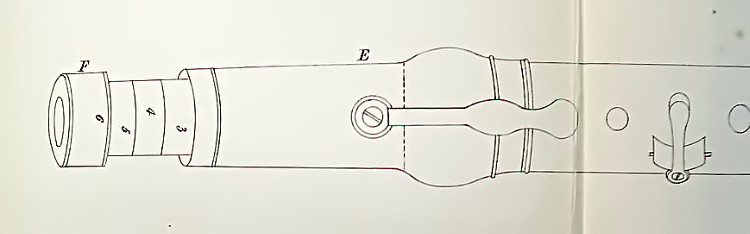

The Foot and Foot RegisterThe bottom joint is 3 inches and 3/8 [86mm] long. This is likewise in two pieces, the longest piece E is 3 inches [76mm] long; the shorter one F is 1 inch and a half [38mm] long. The longest piece E has a key for the note D#, that is to say, for D sharp, and a groove [socket] turned at the lower end to receive the shorter one F. [One end of] F is turned smaller 1 inch [25mm] long, to fit and slide into the groove [socket] of the longest piece E. E is also lined with a metal pipe G, half a inch [12.7mm] diameter and 2 inches and five eights [67mm] long, which comes [protrudes] through the lower end 3/8 of an inch [9.5mm]. The shorter one F is lined with a metal pipe H, and is 1 inch and a half [38mm] long, made to fit and slide on the longer pipe G, and into the groove of the longer piece E, and forms a double sliding joint airtight. Telescopic tubes employed inside Potter's foot and foot register sections. The GraduationsThe sliding joints are divided into several spaces, and figured 6, 5, 4, 3, 2, 1, &c as in the draft or plan. There is an ivory button "i" at the top of the piece A with a screw, which moves the cork up and down. By turning the button round a small bit of ivory comes through the top of the button, and is divided into several spaces, and figured as on the sliding joints. When drawn out to any pitch wanted, the figures must correspond as in the draft.

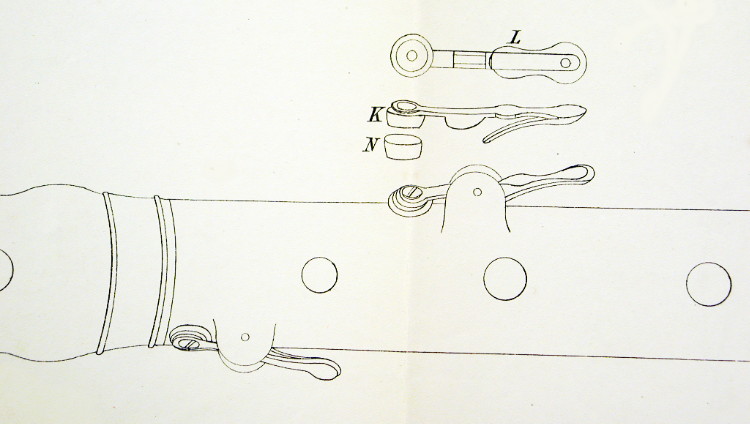

[Image resolution is not adequate to make out the numbering on the ivory stopper indicator. But the sense of it is thus: As you extend the tuning slide and the foot registers, the numbers drop from 6 downward. As you rotate the cap clockwise, withdrawing the stopper, the numbers increase towards 6. On the flute shown in the drawing, the range would appear to be 3 to 6 inclusive.] Bottom joints with additional keys may be used on these flutes by reversing the movement of the cork. [This is an interesting statement. Potter appears to be saying that if you replace the register short-D foot shown with a longer non-register C foot, you will need to back off the stopper setting to compensate. He doesn't nominate how far to back the stopper off.] The Valves, or Pewter PlugsAll the before-mentioned keys are made to stop with a metal conical valve K put on the key L, by the small screw (N), to hang loose as on a swivel. [The hip term "to hang loose" has been around longer than we might have thought!] There is a small hole at the lower end of the key L to receive the screw (M). When the conical keys are fixed to the instrument there is a short piece of metal pipe (N) let in under the centre of the valve, which is countersunk to receive the valve.

These conical valve keys are applicable to any kind of wind instruments wherein keys are used. The notch [slot] cut to fix the key in is lined with metal to prevent wearing by friction. The keys in other respects are as usual on other instruments, and pinned in with a wire and a spring on the lever end. When pressed by the fingers, the key raises the valve, and by raising the finger the spring forces the valve back into the countersunk pipe (N).

ScalabilityIf the German flute intended to be made be of a higher or lower pitch than what is commonly called or known by the term of concert pitch, as it must for that purpose be made shorter or longer, then and in that case the several dimensions of the particulars constituting my said invention should be diminished or extended according to their reciprocal and relative proportions as herein-before given; and if the said keys with valves and countersunk metal pipes are to be adapted or applied to any other musical wind instrument, the sizes and proportions must be varied accordingly. [End of document, apart from closing pleasantries.] RICHD POTTER. Dated 26 November 1785. So, how did Potter's Patent Flute look?I have only a rather sad example to show you, but maybe that is a good thing - it shows us what can go wrong. Firstly, to identification. You can see the name and location, POTTER/LONDON, halfway between embouchure and the slide end of the head. It also appears on the other sections of the flute. You can also make out the word PATENT on the ivory band at the slide end of the head. Unfortunately, the stopper and cap assembly is missing in this flute, and it has the long C foot, rather than the D foot with register. But we can see the remnants of the calibrations on the wooden extension of the barrel.

The downside of including a metal tube inside the wooden head and barrel is well illustrated by the barrel in this image. Like so many, it has cracked wide open, possibly from having moved to Canada at some time in the past. North America's deep winters make for long and intense dry periods where wood shrinkage can cause irresistible cracking forces on lined sections. The head is still holding out - one can only wonder at the forces it is has courageously resisted for over 200 years. Potter's valves seem to be holding up well, although a number of the keys are missing from this flute. They were generally found noisy and troublesome to repair, and were quick to disappear from flute bodies soon after elastic balls (sometimes now called purse pads) were developed in 1810. The valves did hang on longer for the low C and C# keys, and to a lesser extent the Eb key, as the elastic balls were unsuited to normally-open operation and for covering large holes. But this flute does show evidence of another shortcoming in Potter's plan. For reasons that presumably made sense at the time, Potter selected the longest of the three corps de rechange he had used on the flute shown at the top of this article for his new Patent Flute. That meant that the maximum pitch the flute could reach was limited, and certainly proved not high enough for the British High Pitch period late in the next century. Examination of the upper tenon on the LH section tells us that about 13mm (1/2") has been lopped off the top of the section to enable it to reach high pitch. The tuning under those conditions must have been extraordinary! You can enjoy a much prettier example, sumptuously photographed, at David Shorey's Antique Flutes site. VocabularyWe should always take the opportunity to examine these old documents for clues as to what they called the parts of the flute. In this document we see:

|

||

Impact of the PatentSo, there you have it, so far as I know, the first flute patent taken out in England. Did it work to protect Potter's ideas? I don't really know. But maybe that wasn't the real reason to take out the patent. Possibly the real reason, and the real result, was in helping Potter to differentiate his product from those of other makers. The fact that a number of other makers called their flutes Patent, even though they had not sought patent protection, reminds us that, in Industrial Revolution Britain, innovation was prized highly. It seems that Potter's Patent established his reputation not just in England but across Europe and even to America, where many dealers offered Potter's flutes. Perhaps our Canadian example above was one of these. There is an old maxim - "any publicity is good publicity, as long as they spell your name right". Unfortunately, Potter's fame also attracted interest from flute fakers, and they very carefully spelled his name wrongly. Thomas Lindsay tells us:

Perhaps one interesting feature of the flute that was not a highlighted feature of the patent was its narrower bore. Mr Nicholson tells us why a metal-lined narrow bore head was an advantage:

ConclusionsWhatever "mortification and loss" Potter had to endure, it seems his patent did him a lot more good than harm. And the good fortune passed on to his son William Henry Potter, who continued to pump out large numbers of the Patent Flute. Young Potter finally retired in 1837, and subsequently died, unmarried, in 1848, leaving a fortune of ₤30,000. That translates to over ₤2 million today, based on buying power, or ₤20 million based on comparison with the average wages of the times. AcknowledgementsMy thanks to Robert Bigio, London, and the Bate Collection, Oxford for use of the image of the Potter flute that preceded the Patent flute. Related Pages: |